In the global chemical supply chain, transporting corrosive substances safely is a critical operational and regulatory challenge. Acids, alkalis, and other aggressive chemicals can react with standard transport equipment, increasing the risk of danger to human body. As industries expand and cross-border chemical movement continues to grow, the need for specialised containment solutions has become increasingly important.

Lined ISO tank containers are designed to address these risks by combining the structural strength of ISO tanks with internal protective linings that resist chemical attack. By creating a barrier between corrosive cargo and the container’s metal shell, these tanks play a key role in maintaining safety, preserving cargo integrity, and supporting compliant chemical transportation. This guide explores how lined ISO tank containers work, why linings are essential for corrosive chemical transport, and the different lining options available for modern chemical logistics.

What Are Lined ISO Tank Containers?

ISO tank containers are standardized, cylindrical vessels designed to transport liquids, gases, and chemicals across global road, rail, and sea networks. Built to rigorous international standards, these tanks are the backbone of bulk liquid logistics. However, when the cargo is highly aggressive, such as acids or alkalis, the standard metal shell requires an extra layer of defense.

This is where lined ISO tank containers become essential. These tanks feature an internal protective coating specifically engineered to shield the container’s metal structure from corrosive cargo. By creating a barrier between the substance and the shell, the lining prevents hazardous chemical reactions that could otherwise degrade the tank’s structural integrity. For any chemical ISO tank carrying harmful liquids, a proper lining is the primary safeguard against contamination and a critical component of overall transport safety.

Why Lining Matters For Corrosive Chemical Transportation

Corrosive chemicals are inherently reactive. They can eat away at metal surfaces, welds, and seals if the container is not properly protected. The wrong choice of material or the absence of a lining can lead to catastrophic failures such as leaks, spills, and container rupture.

Here are key reasons why lining matters:

1. Protection against chemical attack

Many corrosive chemicals will react with stainless steel or carbon steel, which are commonly used in tank construction. A lining provides a chemical barrier that prevents direct contact between the cargo and the tank metal.

2. Extended equipment life

Lined containers resist wear and degradation, reducing maintenance costs and extending the service life of the container.

3. Improved safety

Protecting the container from corrosion reduces the risk of container failure, which in turn safeguards workers, transport personnel, and the environment.

4. Regulatory Compliance

Many international transport regulations require suitable tank linings for dangerous goods. Using the right lining helps companies meet ISO tank safety standards and hazardous material regulations.

Types Of Linings Used In ISO Tank Containers

Not all linings are created equal. The right lining depends on the chemical properties of the cargo. Some linings are more resistant to specific acids and alkalis, while others offer broader protection or better long-term durability. Below are the primary linings used in lined ISO tank containers.

Rubber Linings

Rubber linings are one of the oldest and most widely used solutions for corrosive liquid transport. They are typically applied as a thick layer of natural or synthetic rubber bonded to the interior surface of the tank.

Advantages

- Excellent resistance to a wide range of acids, alkalis, and chemicals

- Forgiveness of small physical impacts and abrasions

- Relatively low cost compared with some specialised coatings

Limitations

- May deteriorate with certain aggressive solvents

- Limited temperature range compared with some other linings

Rubber linings are ideal for transporting many types of acids and basic solutions where flexibility and abrasion resistance are priorities.

Epoxy/Phenolic Linings

Epoxy and phenolic linings are thermoset coatings that form a hard, chemical-resistant surface. These linings are widely used in chemical ISO tank containers due to their overall robustness.

Advantages

- Superior chemical resistance to a broad range of substances

- Excellent adhesion and long service life

- Good resistance to abrasion and mechanical stress

Limitations

- Less flexible than rubber, making them more prone to cracking under severe thermal expansion

- Application and curing require precision to ensure full protection

Epoxy and phenolic linings are frequently used when transporting industrial chemicals, solvents, and corrosive liquids with moderate reactivity.

PTFE Linings

Polytetrafluoroethylene (PTFE) linings are high-performance fluoropolymer coatings known for their exceptional chemical resistance.

Advantages

- Extreme resistance to nearly all corrosive chemicals

- High thermal stability and low permeability

- A very smooth surface minimises cargo residue and makes cleaning easier

Limitations

- Higher cost than rubber or epoxy linings

- Specialised application process that requires expertise

PTFE linings are ideal for transporting highly aggressive chemicals and substances that might degrade other types of linings.

Advantages

- Strong mechanical properties

- Good chemical resistance across a broad range

- Suitable for heavy-duty applications

Limitations

- The application is complex and requires experienced technicians

- Can be heavier than other lining options

Glass-reinforced linings are used in applications where both chemical resistance and structural reinforcement are required.

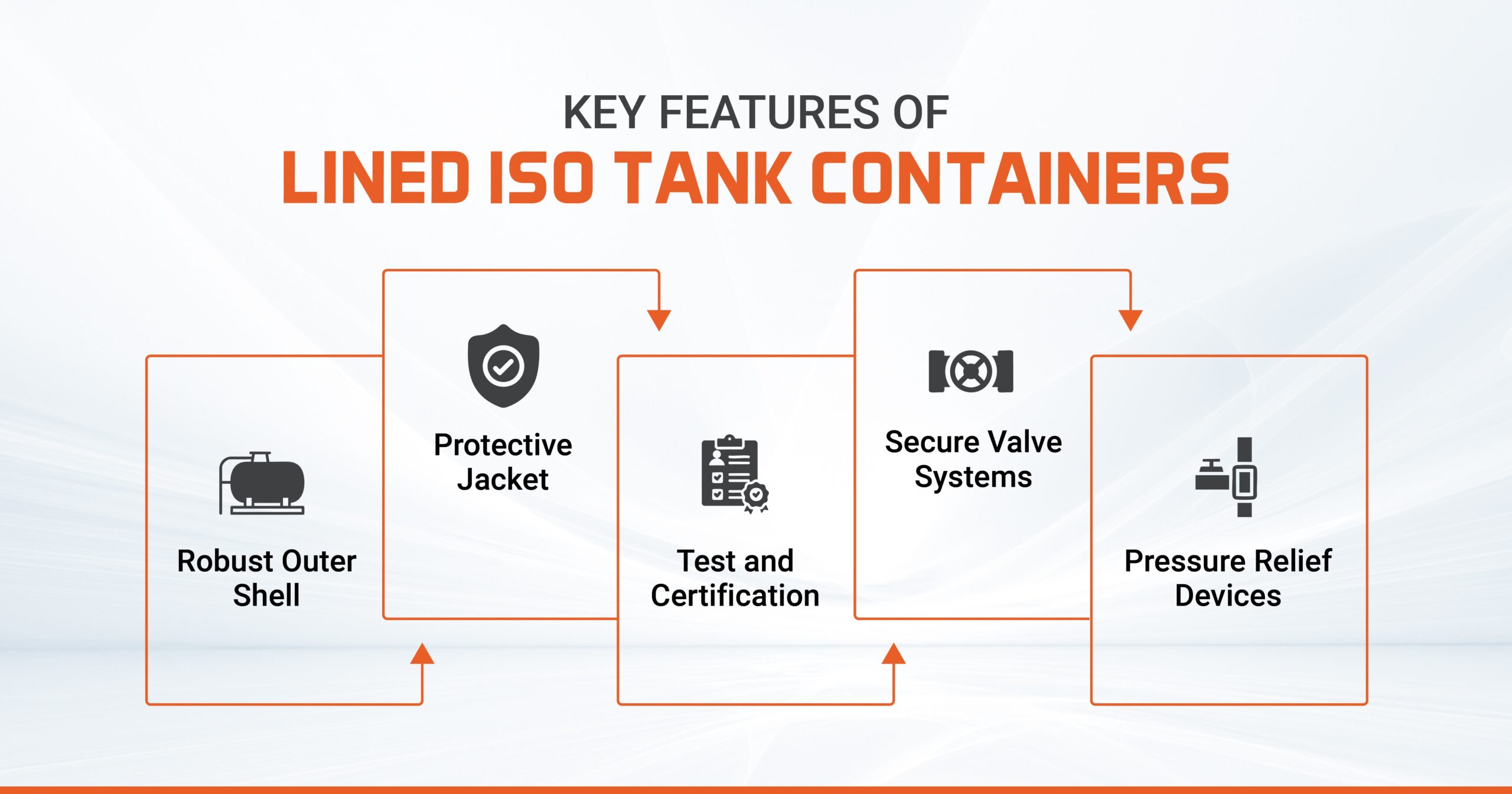

Key Features Of Lined ISO Tank Containers

In addition to the lining itself, several design features enhance the safety and performance of lined ISO tank containers for corrosive chemical transportation:

1. Robust Outer Shell

Container shells are typically made from high-strength steel that provides structural integrity during transport.

2. Protective Jacket

Many tanks include an external jacket that protects the inner shell and lining from physical damage and thermal influences.

3. Pressure Relief Devices

For chemicals that emit gases or vapours, pressure relief valves ensure safe venting and prevent overpressure.

4. Secure Valve Systems

Specialised valves and fittings minimise leaks and ensure secure connections during loading and unloading.

5. Siphon Tube (Dip Tube)

Since bottom valves are a leak risk for acids, a siphon tube allows for top discharge. It extends to the bottom of the tank, allowing cargo to be safely pumped out from the top while keeping the shell’s base solid and secure.

Conclusion

Safe transportation of corrosive chemicals demands specialised equipment and attention to detail. Lined ISO tank containers are engineered to meet these challenges by providing chemical protection, operational safety, and compliance with international standards. Whether you’re moving acids, bases, or hazardous solvents, choosing the right lining, from rubber to PTFE, is critical to protecting your cargo, your crew, and your bottom line.

By understanding the differences between lining types and the key safety features of lined tank containers, shippers can make informed decisions that reduce risk and optimise chemical logistics. Integrating the right lined tank containers into your supply chain not only enhances ISO tank safety, but it also builds resilience and reliability in corrosive chemical transportation.